AGR 301 :: Lecture 15 :: Saccharum officinarum

![]()

Introduction

Sugarcane is an industrial crop with acreage of about 4 million hectares and production to the tune of 300 million tonnes in India. It provides employment to over a million people directly or indirectly besides contributing significantly to the national exchequer. In commercial agriculture, the cane is subjected to various weather conditions and stresses. In Indian subtropics erratic availability of moisture and frequent occurrence of red rot disease severely impair the productivity of cane. Sugarcane is an industrial crop with acreage of about 4 million hectares and production to the tune of 300 million tonnes in India. It provides employment to over a million people directly or indirectly besides contributing significantly to the national exchequer. In commercial agriculture, cane is subjected to various weather conditions and stresses. In the Indian subtropics erratic availability of moisture and frequent occurrence of red rot disease severely impair the productivity of cane.

Importance

- 62% world’s sugar is met from cane

- Sugar requirement is projected at 150 million tonnes for the world

- India alone requires 16-20 million t

- Sugar industry is the largest agro-based industry next only to textiles in India

- At present there are 450 sugar factories

- Average productivity is 14.2 million t (1998)

- Average sugar recovery of 11%

By products in sugarcane industry

- There are many end uses - probably more than 150

- But many of them are of negligible economic interest

- 38 end-products are potentially important

- But four main byproducts of the sugarcane are:

- Cane tops

- Bagasse

- Filter mud / press mud and Spent Wash

- Molasses

- Cane tops

- Cane tops have no real market value

- They can be compared to fair quality fodder with an average feed value,

- when fresh, of about 2.8 MJ of metabolizable energy per kilo of dry matter.

- However cane tops should be collected and transported from the cane fields to the feedlot

- Bagasse

- It is the fibrous residue of the cane stalk left after crushing and extraction of the juice

- It consists of fibres, water and relatively small quantities of soluble solids - mostly sugar

- Utilizations are:

- Electricity

- Particle board

- Paper

- Furfural

- It is a colorless, inflammable, volatile, aromatic liquid

- 25 tonnes of bagasse to produce 1 tonne of furfural

- Furfural has many industrial uses:

- Selective solvent for the refining of lubricating oils

- As an intermediate in the production of nylon and resins

- Methane

- Filter mud / pressmud

- The precipitated impurities contained in the cane juice, after removal by filtration, form a cake of varying moisture content called filter mud

- This cake contains much of the colloidal organic matter anions that precipitate during clarification, as well as certain non-sugars included in these precipitates

- Filter mud / pressmud

- The use of filter mud

- As animal feed has not proved economically rewarding, the main constraints being the magnitude of the drying process involved and the low digestibility of the dried scums

- As soil nutrient there is limitations

- Higher values of C.O.D. and B.O.D .

- Wax percentage in substantial quantity which prevents microbial action

- High concentration of various chemicals which are detrimental to survival of beneficial microflora

- Bio-degradation being exothermic reaction survival of microbes except thermophiles is difficult

- Due to above mentioned difficulties, bio-degradation of pressmud and spent wash is a difficult process

- Molasses

- Molasses is the final effluent obtained in the preparation of sugar by repeated crystallization

- It is the residual syrup from which no crystalline sucrose can be obtained by simple means

- The yield of molasses is approximately 3.0 percent per tonne of cane

- but it is influenced by a number of factors (2.2 to 3.7 percent)

- The specific gravity varies between 1.39 and 1.49, with 1.43 as indicative average

- The composition of molasses varies but, on average, would be as follows:

- Water 20%

- Other carbohydrates 4%

- Sucrose 35%

- Nitrogenous compounds 4.5%

- Fructose 9%

- Non-nitrogenous acids 5%

- Glucose 7%

- Ash 12%

- Other reducing sugars 3%

- For distillery industry

- Alcohol and related products

- Export to some developed countries as raw materials

- It is an ingredient to animals feed

Origin

- India is considered as native to thin cane

- Tropical thick canes from larger islands of Oceana with New Guinea as possible nucleus

- Brandes (1956) – three different movements

- Introduction to Solomon islands - 8000 BC

- Westerly direction to Indonesia and Philippines – 6000 BC

- Fiji, Tonga, Samoa, the Cook islands & Hawaii – 600-1100 AD

World Scenario (Area, production, productivity, in million ha, tonne and t/ha)

Country |

Area |

Production |

Productivity |

Brazil |

6.15 |

455.3 |

74.0 |

India |

4.20 |

281.2 |

66.9 |

China |

1.22 |

100.7 |

82.5 |

Pak |

0.91 |

44.7 |

49.2 |

Asia |

8.81 |

569.8 |

64.7 |

America |

9.48 |

688.3 |

72.6 |

Africa |

1.62 |

92.5 |

57.1 |

World |

20.4 |

1392.4 |

68.3 |

(FAOSTAT, 2006)

Indian Scenario (Area, production, productivity)

State |

Area |

Production |

Productivity (t/ha) |

UP |

2155.8 |

125469.9 |

58.2 |

Maharastra |

501 |

38853 |

77.6 |

TN |

335.4 |

35106.5 |

105 |

Karnataka |

219 |

18267 |

83.4 |

AP |

230 |

17656 |

76.8 |

Punjab |

84 |

4860 |

57.9 |

Gujarat |

197 |

14580 |

74 |

Haryana |

127 |

8180 |

64.4 |

Bihar |

101.3 |

4337.9 |

42.8 |

MP |

55.5 |

2425 |

43.7 |

India |

4201.1 |

281171.8 |

66.9 |

Species of sugarcane

- Cultivated

- Wild species

- S. spontaneum

The plant

- Grass family with tillering capacity

- Above ground parts are

- Stem of stalk with nodes and internodes

- Leaves

- Inflorescence

- Roots

- Sett roots developed from root primordial

- Shoot root , thicker branched

- Buttress roots, fibrous branched

Varieties

- After the introduction of hybridization programme in early 20th century many improved varieties are available

- Varieties for region and season are available in plenty

- SBI, Coimbatore in collaboration with NARS has set up breeding programme

- Breeders of NARS will visit and at a specified period and carry materials

Seasons

- There are four main seasons in TN

- Early – Dec-Jan

- Mid-season – Feb-Mar

- Late – Apr – may

- Special season – June-July

- All India

- Spring – Feb-Mar

- Suru in Maharastra, Eksali in Gujarat & AP

- Autumn – Sep-Oct-

- 13-15 months, supplies sugar for early crushing

- Adsali – July Aug

- 16-18 months

- Increase in yield & sugar recovery

- Though advantageous area is declining due to water problem

- Late planting – beyond March, reduction in duration and yield

Soils

- Cultivated in wide range of soils

- Moderately heavy medium deep (1-2m) loams are better than

- Heavier and shallow soils

- The soil must be of good depth and drainage

- No salt and compaction

Seed bed

- Preparation of good seed bed is essential

- Since the same field is retained for 2-3 years

- Deep ploughing / sub-soiling is needed

- Field Layout

- In India - by adopting two systems viz.,

- Ridge and furrows system

- Flat system.

- There are some special systems

- Trench system

- Deep Trench system

- Paired - row system

- Ring or pit system etc.

Planting materials

- Vegetative propagation

- Known as seed pieces or setts

- Buds on sugarcane germinate and give plants

- Planting materials may be

- Single bud sett or Chip bud

- Two budded setts

- Three budded

- Seedlings raised from nursery

- Seedlings raised by poly bags or

- Tissue cultured seedlings

- For sett planting

- Sugarcane setts are prepared from nursery cane

- Nursery cane is younger than (6-8 months) juice cane

Ideal cane sett

- Ultimate plant stand and yield depends on the type of seed material used. The characteristics of good seed cane material are

- Free from disease and pest infestation

- Age of seed crop is around eight months

- Setts should have healthy buds without any damage in handling and transport

- Buds with higher moisture content, adequate nutrients, higher amount of reducing sugars

- Cane should be free from aerial roots and splits

- Pure in quality

Preparation of setts

- Use of sharp knife to cut setts

- Treat the setts immediately with fungicide solution

- Machine cutting and mechanical planting is also followed in developed counties

- Seed rates & spacing

- Depends up on the spacing

- Spacing varies due to

- Climate

- Method of establishment

- In TN

- 50,000 three budded setts

- 75,000 two budded setts

- 187,500 single budded setts

- Row spacing may vary

- 0.9m to 1.5m and 2.4m

Method of planting

Flat Planting

- In this method, shallow (8-10 cm deep) furrows are opened with a local plough or cultivator at a distance of 75 to 90 cm

- There should be adequate moisture in the field at the time of planting

- The setts are planted in them end to end

- Furrows are covered with 5-7 cm soil

- In most parts of northern India and some tracts of Maharastra, cane is planted by this method

Furrow Planting

- In this method furrows are made with a sugarcane ridger about 10-15 cm deep in northern India and about 20 cm in south India

- Setts are planted end to end

- The furrows are covered with 5-6 cm soil, leaving upper portion of furrows unfilled

- Immediately after covering the setts water is let into furrows

- This method is practiced in parts of eastern UP and in Peninsular India, particularly in heavy soils

Trench Method

- In some coastal areas as well as in other areas where the crop grows very tall and the strong winds during rainy season cause lodging of cane, trench method is adopted to save the crop from lodging

- Trenches at a distance of 75-90 cm are dug with the help of ridger or by manual labour

- Trenches should be about 20-25 cm deep

- Fertilizers (NPK) are spread uniformly in the trenches and mixed thoroughly in the soil

- The setts are planted end to end in trenches

- The tractor-drawn sugarcane planter is a very suitable device for planting cane in trenches

Modified trench system

- Ridges and furrows are opened at 120 cm using a tractor drawn ridger

- The furrow bottom is widened

- As the crop grows while each manuring, only slight earthing up is done so that a trough is maintained through the crop growth

- Here irrigation is given in the cane row itself

- The system has been found highly useful under :

- Saline water irrigated and saline soil conditions

- The salts are leached down from the root zone

- Higher cane yield compared to conventional ridges and furrows

- FYM or pressmud application and trash mulching in this system can further improve cane yield

Special methods of establishment

Single bud direct planting

- In this system single bud setts are planted directly in the field in the furrows at 30-45 cm spacing

- This method is highly economical and sowing of seed material.

- The buds should be healthy

Transplanting technique (STP technique)

- Seedlings are raised in a nursery bed using single bud setts.

- About 6 weeks old seedlings are transplanted

- Advantages by adopting this system are

- Saving in the seed cost

- Only about 2-3 t/ha against the normal 8-10 tonnes/ha.

- Synchronous tillering leading to uniformly maturity

- Sufficient time availability to prepare the main field

- Saving of 2-3 irrigations

- Possibility of increased cane yield

- Better weed management

- Efficient fertilizer management

Partha" method

- A technique developed by Mr. S.V. Parthasaradhy an eminent sugarcane scientist.

- Suggested for water logged or excess soil moisture conditions (coastal Andhra Pradesh and Tamil Nadu during N-E monsoon period)

- In this method

- three eye budded setts are planted in a slanting position, 60° to the vertical, in the wet furrow or half-way on the ridges

- Usually one eye bud is thrust into the soil and the remaining two will be above, which will sprout

- Once the monsoon recedes, the in situ sprouted setts are pressed down into the soil and made to lie horizontally

- Soil is put to the base

- At this stage, the crop is manured

Paired row double side planting system

Drippers at 75 cm spacing 12 mm laterals with a lateral spacing of 195 cm

Tractor drawn sugar cane planter

Pit method /Ring pit method

A new method of sugarcane cultivation is called pit method or ring pit method, which is cost-effective and at the same time helps farmers get a higher yield is slowly catching on. Several farm trials have proved that by adopting this method, the yield can be increased to two or three times compared to the normal row-to-row planting technique. In the pit method, the crops are raised in pits at the spacing of 180 cm between rows and 150 cm between individual pits in a row. The pits are dug using specially designed tractor drawn power tillers.

The pits are then filled with top soil, 5 kg of farmyard manure (FYM), 100 gms gypsum and 125 gms super phosphate and watered well before planting. About 16 double budded or 32 single budded setts were used for planting. The setts were collected from the eight-month-old plants and were treated with 0.1 per cent carbendazim for 10 minutes before planting. About 60,000 double budded setts were required for planting in one hectare. The pits were irrigated daily for an hour through drip fertigation. Detrashing was done on fifth month after planting and the plants were tied without lodging by dried leaves.

The growth of the crop was vigorous and they matured at the eighth month after planting. Due to the equal spacing maintained on all the sides the plants grew steadily and the nutrition supplied through drip fertigation reduced the crop duration. The continuous supply of nutrition and spacing induces the early physiological maturity that was the major benefit. All the shoots are of the same age, so there is uniform growth and sugar accumulation in the canes. Sufficient space between the clumps and row to row allows sufficient light and air circulation, which is important for good growth of the crop.

The most important factor was that the sugarcane setts were placed at a depth, which were always moist, hence, in case of drought, or non-availability of water the yield was not affected. Under the conventional system, farmers in Tamil Nadu are at present harvesting about 130 tonnes a hectare

Ring pit method

Measures to obtain higher germination

- Using disease free healthy setts

- Careful preparation of setts without damaging the buds or setts

- Planting freshly prepared and treated

- Trash mulching under

- moisture stress and hot weather and late planted conditions

- Seed treatment using a fungicide

Manures for Sugarcane

- Apply FYM / Compost during field preparation

- Inorganic fertilizers:

- For Coastal and flow irrigated areas

- 270 : 112.5: 60 N: P2O5: K2O kg /ha

- N & K applied in three equal quantities at

- 30, 60 and 90 DAG

- N may be coated with neem cake @20%

- For Lift irrigated areas

- 225 : 112.5: 60 N: P2O5: K2O kg /ha

- For Jaggery producing areas

- 175 : 112.5: 60 N: P2O5: K2O kg /ha

- For those soils deficient in …

- In iron : 100 kg ferrous sulphate /ha

- In Zinc : 37.5 kg Zinc sulphate

- Foliar application and drip fertigation can

- Reduce N dose

- Increase cane yield

- Save ground water pollution by fertilizers

- Azospirillum application can enhance the growth

- Band placement of fertilizer is another method by which losses can be minimized

Irrigation

- To support and sustain a vigorous nursery crop, irrigating at optimum levels in important

- Any shortage in the irrigation would lead to reduced sett yield

- Moisture stress would pre-dispose the crop to the attack of some pests and diseases

- Irrigation at IW/CPE ratio of 1.0 is ideal

- According to moisture depletion irrigating at 25% depletion of available soil moisture (ASM) may be ideal

- This in practical terms means:

- Once in 6-7days in a loamy soil and

- At around 10-12 days in heavy clay soil

Weed control

- A weed-free environment is absolutely essential

- Deep ploughing and removal of perennial weeds

- Pre-emergence application of

- Atrazine 1.75kg or Oxyflurofen 0.75 lit/ha on 3-4 days of planting using knapsack sprayer

- Post-emergence application of

- Gramaxone 2.5 lit + 2-4,D Sodium salt 2.5 lit/ha as directed spray on 21 DAP

- Hand weeding before each manuring

- Other cultural operations and precautions

Cultural operations

- Important cultural operations in sugarcane in addition to weeding, manuring and irrigation are

- Earthing up

- Detrashing

- Propping and

- Flowering control

Earthing-Up

- This practice is followed where furrows are practiced

- Earthing up are 2-3times during crop period.

- The first earthing-up is known as "partial earthing-up and

- To cover the fertilizers

- To provide anchorage to root system

- The second operation is "full earthing-up".

- Full earthing-up is done after final manuring (90-120 days coinciding with peak tillering)

- The soil from the ridge is thrown on both sides towards cane rows and the furrows will become as ridges and ridges as furrows

- The furrows so formed are used for irrigation

Wet earthing up

- Done around 6months age of the crop

- The furrows are irrigated and the wet soil from furrows is taken and plaster the ridges

- It checks late tillering and watery shoots

- Heavy earthing up is useful during floods

- When the flood water recedes, the excess water from earthed-up soil drains out quickly thus providing aeration

Hoeing

- This operation is done where soil crust formation is very common

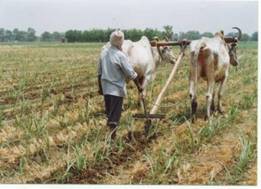

- In sub tropics hoeing is done after germination is over using a bullock drawn or a tractor - drawn harrows

- While carrying out this operation some of the germinated setts may be uprooted and they are pressed down manually

Detrashing

- On an average a stalk may produce30-35 leaves

- All are not useful for effective photosynthesis

- Only the top 8-10 leaves are sufficient

- Most of the bottom leaves are dried will not participate in photosynthesis

- At the same time they drain out the food materials which otherwise could be used for stalk growth

- Therefore it is important to remove the dry and lower leaves

- This operation is known as detrashing

- Detrashing helps in clean cultivation

- Easy movement of air within the crop canopy

- Reduce certain pests like scales mealy bugs, white fly etc.,

- Easy entry into the field

- Avoids bud germination due to accumulation of water in the leaf sheath

- Easy to take up cultural operations including sprayings

- Easy to harvest, obtaining clean canes for milling

- Detrashed leaves can be used for

- Mulching in the furrows or

- Used for composting

- Infested leaves with pest or disease may be burnt out

Propping

- Tying the canes by using the lower bottom leaves to check lodging of cane

- Propping can be either done for each row or two rows can be brought together and tied

- It is for:

- Prevention the lodging

- Extensively followed in coastal belt where cyclone effect is very severe

- Lodging also very common in

- Tall varieties

- Top growth is heavy and where the growth habit is not erect, and

- The varieties with less fibre content

Lodging leads to several problems

- Cane breakage and thus loss of stalk number at harvest loss

- Lodged canes are easily infested by certain pests and diseases

- Damage by rats and rodents

- Bud sprouting leads to reduced cane quality

- Aerial root formation affects cane quality

- difficult to irrigate and harvest the cup

To prevent lodging

- Heavy earthing up

- Propping

- Paired row planting with earthing up

- Deep trench planting

- Selection of varieties resist lodging

- Raising wind breaks along the field borders

- Application of potassium

Removal of water shoots

- Water shoots are late formed tillers or side shoots which are robust and fast growing.

- They originate mainly due to excess water supply, heavy and late manuring, inadequate earthing up

- These water shoots contain lot of water, low sucrose and more of reducing sugars

- Water shoots affect the growth of adjacent stalks

- They harbor insect pests and when they are milled sugar recoveries are low because of reduced juice quality

- Therefore removal of water shoots whenever they appear

- Water shoots can be used as cattle feed

Control of flowering

- In commercial sugarcane cultivation, flowering is not desirable

- Once the plant flowered the cane growth stops and starts ripening

- If not harvested immediately reversion of sugars, increase in fibre, pith formation, cane breakage etc.

- The deterioration is much faster if it is summer

- Solution

- Non-flowering or shy flowering varieties can be used where flowering is a severe problem

- Controlled irrigation

- Change of planting period

- Use of growth regulating substances

- Spraying of ethrel at 500ppm, twice or 1000ppm once at floral initiation

Ratoon Management

- The crop raised from planting cane sett is called plant crop

- After the harvest of plant crop stubble sprouts and gives rise to succeeding crop called as ratoon crop

- The practice of taking up ratoon crop is called ‘ratooning’

Ratooning ability

- Is generic, based upon ability ratoon varieties are classified as:

- Good or poor ratooner

- Co 1148, Co 419, Co 740 are some examples for good ratooners

- Ratooning has following advantages:

- Reduction in the cost of field preparation, planting material, operation cost

- Saving in field duration – ratoon matures earlier than plant crop

- Ratoon may give equal yield that of plant crop

Ratooning is common practice

- Number ratoon varies

- In Cuba 10-11 crops

- South Africa & USA 4-6 crops

- Hawaii, Brazil and Australia 2-3

- In India ratoon yield is generally poor since

- Very little attention to manure ratoon

- 30-40% area is under ratoon in India

- The average productivity is low

Ratoon management

- Select variety suitable during plant crop

- Plant crop should be harvested at right maturity

- Delayed harvest to be avoided

- Harvesting close to the ground with sharp cutting

- Stubble shaving to 4-6cm is recommended if no uniform cut at harvest

- Remove the trash but do not burn it

- Irrigated the field properly

- Shoulder breaking or off-barring to remove decayed stubbles

- Gap filling with sprouted setts or seedlings

- Ratoon is less efficient in N utilization hence 25% additional N from 5-7 days after ratooning is desirable

- P & K should be judiciously

- Spraying of FeSO4 @ 2.5kg/ha in 150 litres on 15th day if chlorotic symptom is noticed

- If persists repeat twice at 15 days interval

- In the last spray add 12.5kg urea

- After cultivation practices to be done more effectively

- Ratoon requires more plant protection

- Grassy shoot disease, ratoon stunting

Maturity and harvest

- Ripening of sugarcane refers to rapid synthesis and storage of sucrose in the stalk

- Accumulation of sugar in the stalk starts soon after completion of elongation phase

- Glucose produced during photosynthesis is not utilized for conversion but stored as sucrose

- When the concentration exceeds 16% in the juice and 85% purity the cane is said to be matured

- As the crop advances in maturity:

- Water content decreases

- Sucrose content increases

- Reducing sugars decreases

- Both organic and inorganic non-sugars also decreases

- At peak maturity sucrose content is at maximum and non-sugars at minimum

- Assessing maturity

- Use of hand refractometer - Brix reading

- Assess the maturity by HR meter survey – 18-25% indicates optimum maturity

- When the reading between top and bottom is 1:1 – is right time to harvest

- If delayed

- Sucrose content decreases

- Non-sugars increases

- Fibre content increases

- Ripening is influenced by number of factors

- Climate

- Nutrition

- Variety

- Cool dry weather is the key factor

- Bright sunshine

- Day temp 28-30C

- Night temp 12-14C

- RTD (Relative temp disparity) decides

- Ripeners

- Spray Sodium metasilicate 4kg in 750 litres /ha 6 months after planting

- Repeat at 8th & 10th months

- and not at declining phase

- Polaris and Ethrel are most extensively used in Hawaii

- Polaris @ 5 kg in 600 l /ha

Cropping systems

- Intercropping

- Since a slow grower during initial 2-3 months may be an intercrop raised

- The crop should not affect cane yield

- Marketability, ability and feasibility decides the short crops

- Pulses, potato, onion etc are some

- Sequential cropping - Rotations

- After sugarcane 1 or 2 or 3 crops

- Rice based cropping system for one year

- Wheat based

- Sugarcane-banana- rice based crop rotations

-

Multiple choice questions

- By product of sugarcane is _______

a. Spentwash b. Bagasse c. Molasses d. all these

- The fibrous residue of the cane stalk left after crushing and extraction of the juice is called _______

a. Spentwash b. Bagasse c. Molasses d. all these

- Bagasse is used for production of__________

a. Electricity b. paper c. methane d. all these

- The precipitated impurities contained in the cane juice, after removal by filtration is called _______

a. Pressmud b. Bagasse c. Molasses d. all these

- The final effluent obtained in the preparation of sugar by repeated crystallization is ________

a. Pressmud b. Bagasse c. Molasses d. all these

- The yield of molasses is approximately ________ % per tonne of sugarcane

a. 5 b. 7 c. 3 d. 10 - Sucrose content of molasses is _______

a. 45 % b. 35 % c. 25 % d. 55 % - Glucose content of molasses is _______

a. 5 % b. 7 % c. 10 % d. 12 % - Ash content of molasses is _______ <

a. 12 % b. 7 % c. 10 % d. 15 % - Total world production of sugarcane is _______ m tonnes

a. 1255 b. 1155 c. 1355 - Total production of sugarcane in India is _______ m tones

a. 275 b .265 c. 300 - Productivity of sugarcane is high in which of the following state

a. Maharastra b. Tamil Nadu c. Punjab - Average productivity of sugarcane in India is ______ t /ha

a. 99 b. 89 c. 67 - Cultivated species of sugarcane is ______

a. S. spontaneum b. S. robustum c. S. officinarum - Wild species of sugarcane is ______

a. S. barberi b. S. robustum c. S. officinarum - Seed rate for two budded setts is ________ setts /ha

a. 50,000 b. 75,000 c. 1,87,500 - Seed rate for three budded setts is ________ setts /ha

a. 50,000 b. 75,000 c. 1,87,500 - Seed rate for single budded setts is ________ setts /ha

a. 50,000 b. 75,000 c. 1,87,500 - Latest planting technique developed by TNAU in sugarcane is ______

a. Furrow planting b. Trench method c. Pit method - Fertilizer dose recommended for coastal and irrigated areas is _____ kg NPK/ha

a. 225 : 112.5 : 60 b. 270 : 112.5 : 60 c. 175 : 112.5 : 60 - Fertilizer dose recommended for lift irrigated areas is _____ kg NPK/ha

a. 225 : 112.5 : 60 b. 270 : 112.5 : 60 c. 175 : 112.5 : 60 - Fertilizer dose recommended for jaggery producing areas is _____ kg NPK/ha

a. 225 : 112.5 : 60 b. 270 : 112.5 : 60 c. 175 : 112.5 : 60 - Removal of dried and older leaves in sugarcane is called _______

a. Mulching b. Propping c. Detrashing - Tying the canes by using the lower bottom leaves is called _____

a. Mulching b. Propping c. Detrashing - The late formed tillers or side shoots which are robust and fast growing are called

a. Sword suckers b. water shoots c. sprouts - Flowering in sugarcane is called _______

a. Arrowing b. Sprouting c. Tillering - _________ % of brix reading indicates the maturity of sugarcane

a. 16 – 18 b. 18 – 25 c. 25 – 27 - Ripening in sugarcane is enhanced by spraying _________

a. Sodium metasilicate b. Polaris c. Ethrel d. all these are correct

| Download this lecture as PDF here |

![]()