AENG 252 :: Lecture 05 :: DRYING – GRAIN DRYING, TYPES OF DRYING, TYPES OF DRYERS, IMPORTANCE OF DRYING

![]()

- Permits long time storage of grain without deterioration

- Permits continuous supply of product thro’ out the year

- Permits early harvest which reduces field damage and shattering loss

- Permits the farmers to have better quality product

- Makes products available during off season

Drying theory

- Convection process in which moisture from a product is removed

- The water content of agricultural product is given in terms of moisture content

- They gain or loose moisture as per the atmospheric conditions

- Moisture migration into or from a product is dependent on the difference of vapour pressure between atmosphere and product

- If the vapour pressure of grain is greater than atmospheric vapour pressure, transfer of moisture from grain to atmosphere takes place

- If the atmospheric vapour pressure is greater than grain vapour pressure, grain absorbs moisture from atmosphere

Drying rate periods

Divided into 3 periods

- Constant rate period

- First Falling rate period

- Second falling rate period

Constant rate period

- Moisture migration rate from inside of product to its surface is equal to the rate of evaporation of water from surface

- This period continues till critical moisture content is reached

- Critical moisture content: Moisture content of a product where constant rate drying ceases and falling rate starts

- This period is very short for agricultural products

- Drying of sand and washed seeds takes place in constant rate period

Falling rate period

- Most of the agricultural products are dried in falling rate drying period

- Movement and diffusion of moisture in interior of grains controls the entire drying process

Controlled by

- Migration of moisture from interior of grains to upper surface due to water vapour diffusion

- Removal of moisture from the surface

- Divided into two periods

- First falling rate period

- Second falling rate period

First falling rate

- Unsaturated surface drying

- Drying rate decreases because of the decrease in wet surface area

- Fraction of wet surface decreases to zero, where first falling rate ends

Second falling rate

- Sub surface evaporation takes place & it continues until the equilibrium moisture content is reached

Mechanism of drying process

- Movement of moisture takes place due to

- Capillary flow – Liquid movement due to surface forces

- Liquid diffusion – Liquid movement due to difference in moisture concentration

- Surface diffusion - Liquid movement due to moisture diffusion of the pore spaces

- Vapour diffusion – vapour movement due to moisture concentration difference

- Thermal diffusion - vapour movement due to temperature difference

- Hydro dynamic flow – water and vapour movement due to total pressure difference

Thin layer drying

- Process in which all grains are fully exposed to the drying air under constant drying conditions i.e. at constant air temp. & humidity.

- Up to 20 cm thickness of grain bed is taken as thin layer

- All commercial dryers are designed based on thin layer drying principles

- Represented by Newton’s law by replacing moisture content in place of temperature

M-Me/Mo-Me = e -Kq

M – Moisture content at any time q, % db

Me- EMC, %db

Mo – Initial moisture content, %db

K – drying constant

q - time, hour

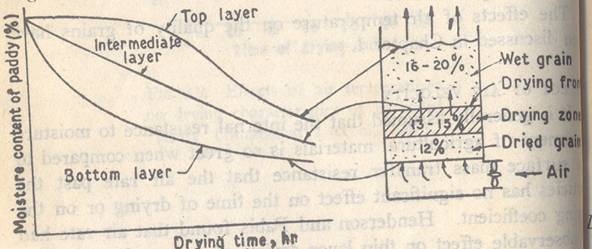

Deep bed drying

- All grains are not fully exposed to the same condition of drying air

- Condition of drying air changes with time and depth of grain bed

- Rate of airflow per unit mass of grain is small

- Drying of grain in deep bin can be taken as sum of several thin layers

- Humidity & temperature of air entering & leaving each layer vary with time

- Volume of drying zone varies with temp & humidity of entering air, moisture content of grain & velocity of air

Deep bed drying characteristics at different depths

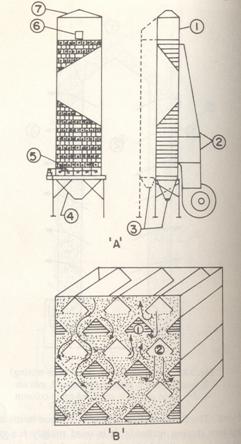

Continuous flow dryer

- Columnar type dryer in which wet grains flow from top to the bottom of the dryer

- Two types

- Mixing

- Non-mixing

Mixing

- Grains are diverted in the dryer by providing baffles

- Use low air flow rates of 50-95 m3/min/tonne

- Zig-zag columns enclosed by screens are used to achieve mixing

- High drying air temperature of 65°C is used

Baffle dryer

- Continuous flow mixing type dryer

- Consists of receiving bin, drying chamber fitted with baffles, plenum fitted with hot air inlet

- Baffles are fitted to divert the flow & also for mixing

- Grain fed at the top & move downward in a zig-zag path where it encounters a cross flow of hot air

- Bucket elevator is used to recirculate the grain till the grain is dried to desired moisture level

- Uniformly dried product is obtained

Mixing type baffle dryer

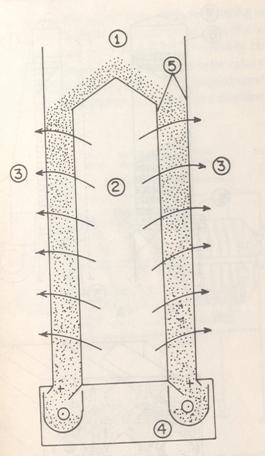

Non-mixing

- Grains flow in a straight path

- Baffles are not provided and drying takes place between two parallel screens

- High airflow rates can be used

- Drying air temp. of 54°C is used

- Feed hopper

- Plenum chamber

- Exit air

- Dry grain outlet

- Screened grain column

Continuous flow dryer (Non-mixing)

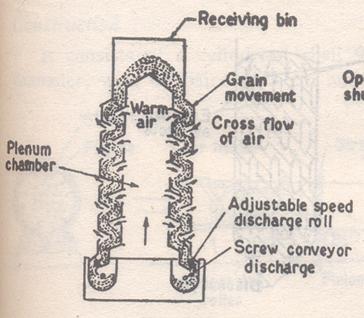

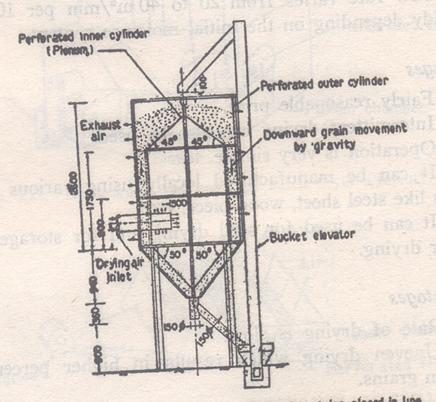

Recirculatory Batch dryer

- Continuous flow non mixing type

- Consists of 2 concentric circular cylinders, set 15-20 cm apart

Bucket elevator is used to feed & recirculated the grain

Centrifugal blower blows the hot air into the inner cylinder, acts as a plenum

Grain is fed at the top of the inside cylinder; comes in contact with a cross flow of hot air

The exhaust air comes out through perforations of the outer cylinder

Grain is recirculated till it is dried to desired moisture content

Drying is not uniform as compared to mixing type

Recirculating batch dryer

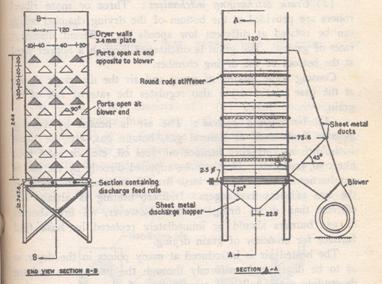

LSU dryer

- Developed at Louisiana state university (LSU)

- Continuous mixing type dryer

- Developed specifically for rice to ensure gentle treatment, good mixing & good air to grain contact

- Consists of rectangular chamber, holding bin, blower with duct, grain discharging mechanism and air heating system

- Layers of inverted V shaped channels are installed in the drying chamber; heated air is introduced through these channels at many points

- Alternate layers are air inlet & outlet channels; arranged one below the other in an offset pattern

- Inlet port consists of few full size ports & two half size ports; all ports are of same size arranged in equal spacing

- Ribbed rollers are provided at the bottom of drying chamber for the discharge of grain

- Capacity varies from 2-12 tonnes

- Recommended air flow rate is 60-70 m3/min/tonne

- Air temp. are 60 &85°C for raw & parboiled paddy

- Uniformly dried product can be obtained

- Can be used for different types of grain

- High capital investment

LSU Dryer

|

|

LSU Dryer

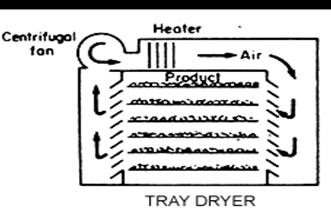

Tray driers

- In tray dryers, the food is spread out, generally quite thinly, on trays in which the drying takes place.

- Heating may be by an air current sweeping across the trays, or heated shelves on which the trays lie, or by radiation from heated surfaces.

- Most tray dryers are heated by air, which also removes the moist vapours.

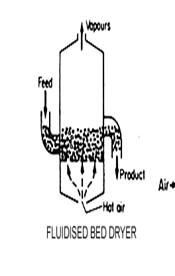

Fluidized Bed Dryers

In a fluidized bed dryer, the food material is maintained suspended against gravity in an upward-flowing air stream.

Heat is transferred from the air to the food material, mostly by convection

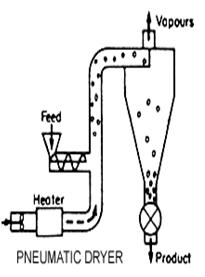

Pneumatic Dryers

- In a pneumatic dryer, the solid food particles are conveyed rapidly in an air stream, the velocity and turbulence of the stream maintaining the particles in suspension.

- Heated air accomplishes the drying and often some form of classifying device is included in the equipment.

- In the classifier, the dried material is separated, the dry material passes out as product and the moist remainder is recirculated for further drying

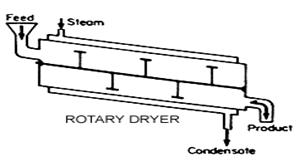

Rotary Dryers

- The foodstuff is contained in a horizontal inclined cylinder through which it travels, being heated either by air flow through the cylinder, or by conduction of heat from the cylinder walls.

- In some cases, the cylinder rotates and in others the cylinder is stationary and a paddle or screw rotates within the cylinder conveying the material through.

| Download this lecture as PDF here |

![]()