AENG 252 :: Lecture 02 :: WINNOWING – MANUAL AND POWER OPERATED WINNOWERS, CARE AND MAINTENANCE

![]()

Wind winnowing is an agricultural method developed by ancient cultures for separating grain from chaff. It is also used to remove weevils or other pests from stored grain. Threshing, the separation of grain or seeds from the husks and straw, is the step in the chaff-removal process that comes before winnowing. "Winnowing the chaff" is a common expression. In its simplest form it involves throwing the mixture into the air so that the wind blows away the lighter chaff, while the heavier grains fall back down for recovery. Techniques included using a winnowing fan (a shaped basket shaken to raise the chaff) or using a tool (a winnowing fork or shovel) on a pile of harvested grain

Winnowing, the process of separating quality grains from chaff, is a crucial process in the cultivation of paddy. The traditional way of winnowing is making the dried grains fall from a height using shovels and a sieve. The quality grains which are heavy fall vertically while the weightless chaff and straw get blown away by the wind. Thus, winnowing is effective only when there is a wind. Farmers often have to wait for hours for the wind to blow before they could start the process of winnowing.

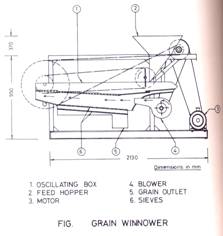

Grain winnower

This machine winnows the paddy already threshed by a paddy thresher or other means. It has a feeding hopper at the top to receive the threshed paddy with other impurities. It discharges the threshed paddy over a scalper and removes bigger size impurities. A blower provided at bottom sends a stream of air against the grain falling through the scalper, which separates the straw, chaff and other impurities. The dust, chaff and straw are collected separately and cleaned paddy is taken out through another outlet near the bottom of the unit. The capacity of unit is 625 kg/h and the unit is operated by one hp motor.

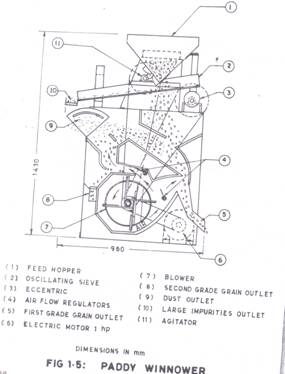

Paddy winnower

The machine winnows paddy already threshed by the paddy thresher or by other means. It has a feed hopper at the top to receive the threshed paddy, chaff and straw bit. A blower provided at the bottom sends a stream of air which separates straw, chaff and other impurities. The dust, chaff and straw come out through an opening and cleaned paddy is taken out through another spout. The unit is continuous type and operated by one hp electric motor.

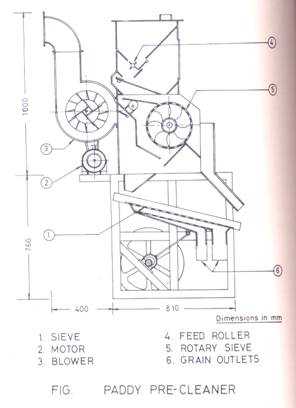

Paddy precleaner

Paddy precleaner is used to remove appendages, glumes and foreign matter. The pre-cleaner is provided with an aspirator, a rotating scalping sieve and horizontal reciprocating grading sieve. By suitably changing the sieve, it can also be utilized for other seeds. By using the pre-cleaner, the efficiency of cleaner cum grader is improved. It also removes both smaller and larger size impurities and the dust from the grain. The capacity of the unit is 150 kg/h and it is operated one hp electric motor. The efficiency of the unit is 91%.

| Download this lecture as PDF here |

![]()